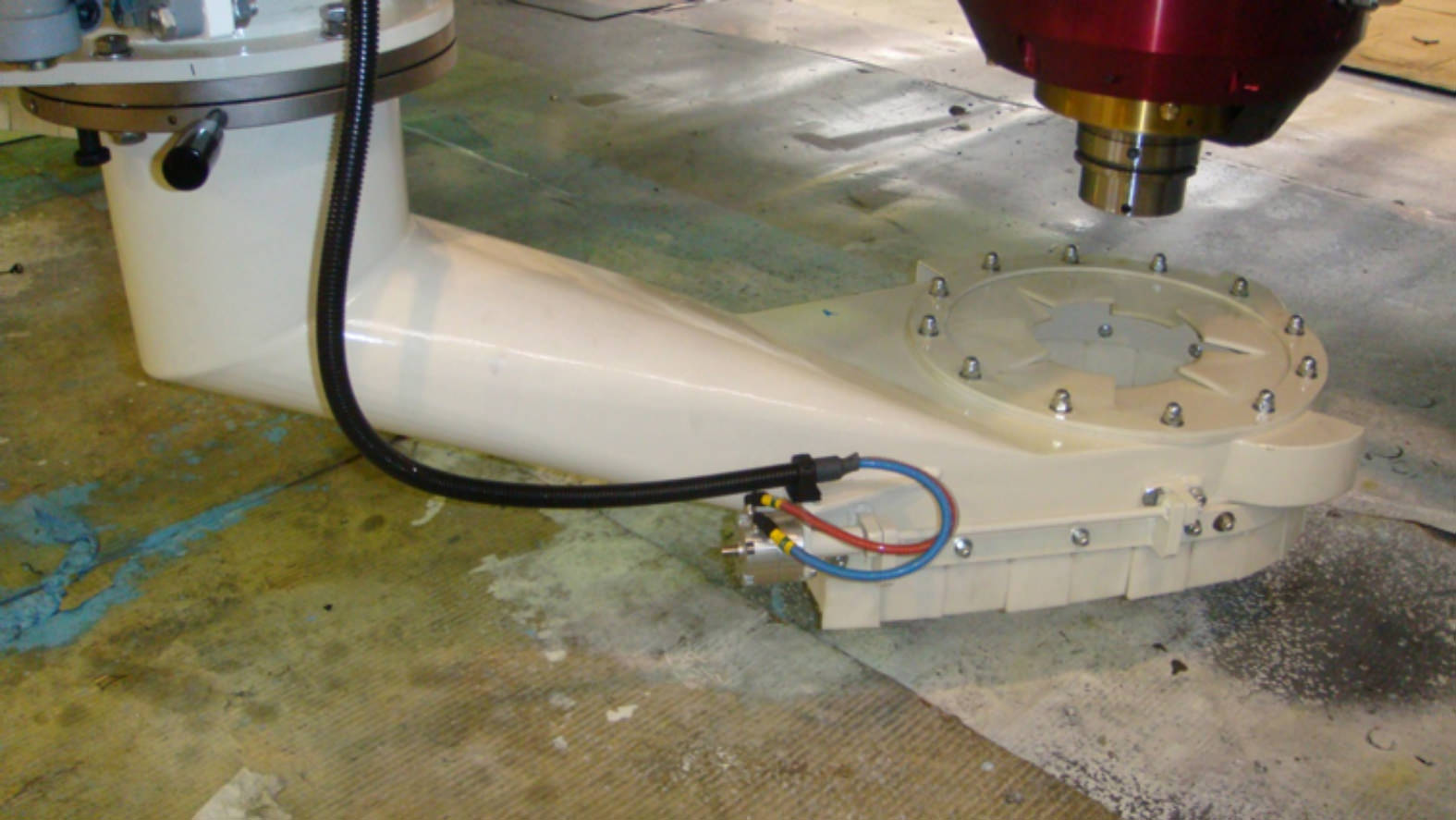

Enclosed collection

Enclosed collection

We mainly use the local exhaust technique by carrying out enclosed collection (collection at source). Beforehand, we proceed with measurements of your installation and kinematic analysis of your machine, guaranteeing optimal incorporation of our equipment into your production process. Using these measurements, we define a suction collector customised to the machine or machining operation being considered.

The advantages of enclosed collection:

- Adapted to your machine or machining phase: Guarantees the desired result.

- The hood shields and interrupts the trajectory of the chips during machining. No dispersion.

- Closeness to sources reduces energy costs: Reduced energy costs compared with other collection methods.

- The product is durable with easy maintenance: low maintenance costs, fast return on investment.

It is the most effective method for optimal retrieval of chips at the lowest cost. It is possible to add optional extras for the machining process, for example: automatic withdrawal for setting up an extra collector or a tipping system on retractable pivot, etc.

Use of enclosed collection:

Composites or metal chips, dust, including highly-abrasive dust.